Window profile processing is no longer a tiring task!

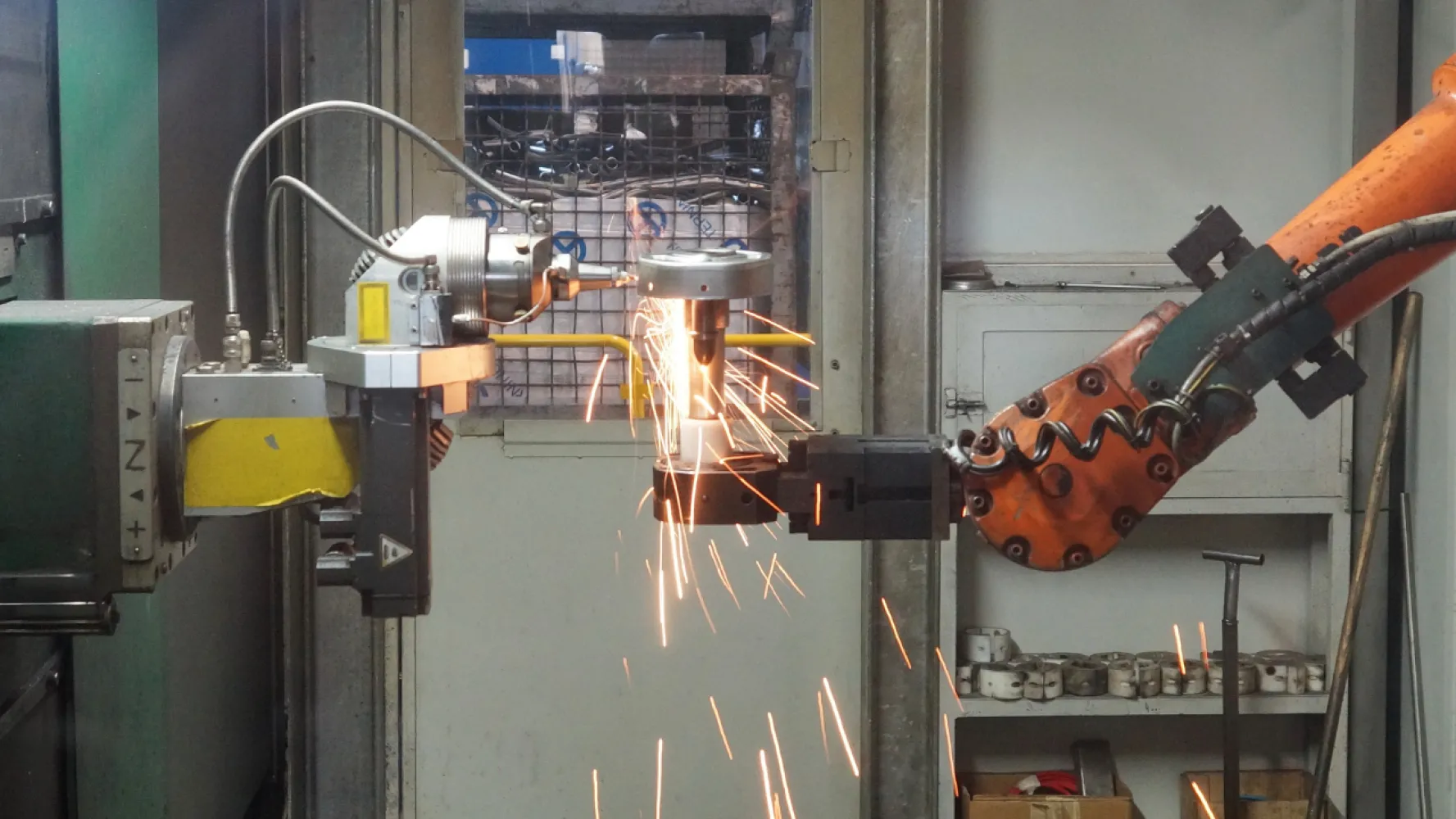

Profile processing mainly includes two processes: huge profile cutting (cut into specific profiles according to typesetting requirements) and profile drilling (use matching drilling and milling procedures to drill and cut grooves on profiles).

In the process of profile processing, to ensure the maximum use of profiles, it is necessary to add a typesetting process. Therefore, “small quantity but great variety” becomes a processing requirement.

In this kind of scenarios, manual operations are often faced with inefficient and error-prone situations. The overall solution of Leantec Robot + RFID + database management came into being for this reason.

Profile automatic production line solution

Leantec Robot + Profile Craft Package + RFID Intelligent Storage + Cloud Monitoring.

01 Profile Craft Package

。Customized process package, which can meet the needs of “small quantity and great variety”

。Adopt robot tool coordinate system to realize high-precision pick and place action

。Intelligent central control system realizes remote control and production line monitoring.

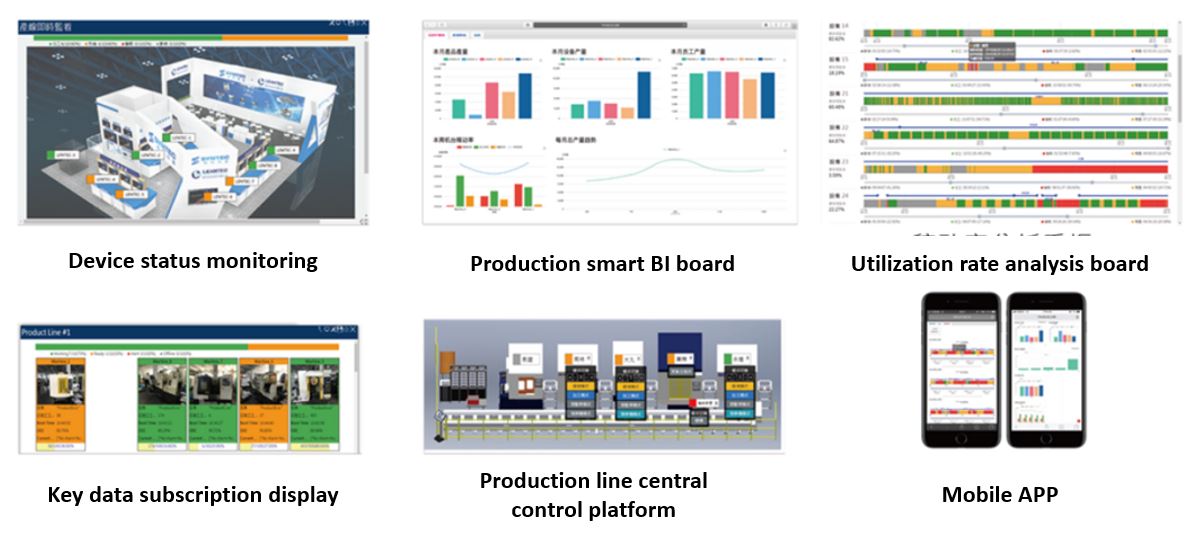

02 RFID Intelligent warehousing

Using RFID (Radio Frequency Identification) to realize intelligent warehousing.

03 Cloud monitoring

A flexible design which can create personalized board according to the needs of factory managers. It will image the data taken to quickly expose all production conditions and make factory management more transparent.

Solution advantages

• Meets a variety of lengths and shapes.

• Provide you with a complete solution, from sawing to drilling and milling.

• Open secondary development function, support customized professional process package.

• The blessing of central control and cloud makes the smart factory within reach.

We will bring more robot application solutions to help you achieve digitization, automation, and intelligence soon. See you in the next article!

16 Feb 2023